Applications

Contact Us

Office Add:Room201,Unit2,Building7th,Huarunyuefu,No.27ChangxingSd, Wanbailin District,Taiyuan,Shanxi PR.China.

1.Drinking Water Purification

This includes the purification of surface water, rivers, lakes, green algae, rural groundwater, deep purification in urban waterworks, pre-filtration in household central water purification systems, purification of household direct drinking water, and purification of bottled and barreled water.

Activated carbon, with its well-developed pore structure and strong adsorption capacity, has become a core material for drinking water treatment, especially in dealing with surface water pollution, sudden pollution incidents and improving terminal water quality, with remarkable effects. The following is a detailed description of the main application sections of activated carbon in the field of drinking water:

|

Activated carbon in the field of drinking water |

|||

|

Application Section |

Process object |

Activated carbon TYPE |

Key removal effect |

|

Surface water purification |

Algal toxins, ammonia nitrogen, organic matter |

(GAC) |

TOC has decreased by over 50%, ammonia nitrogen is nearly 100% |

|

Emergency processing |

Heavy metals, petroleum products |

(PAC) |

The removal rate of heavy metals is over 90% |

|

Control of disinfection by-products |

Residual chlorine, THMs precursors |

GAC/PAC |

The residual chlorine is completely adsorbed |

|

Advanced treatment(O₃-BAC) |

Refractory organics |

Biological activated carbon |

The COD is reduced by 60 to 80% |

|

Household water |

Unpleasant smell, residual chlorine |

Coconut shell carbon filter element |

The taste has been significantly improved |

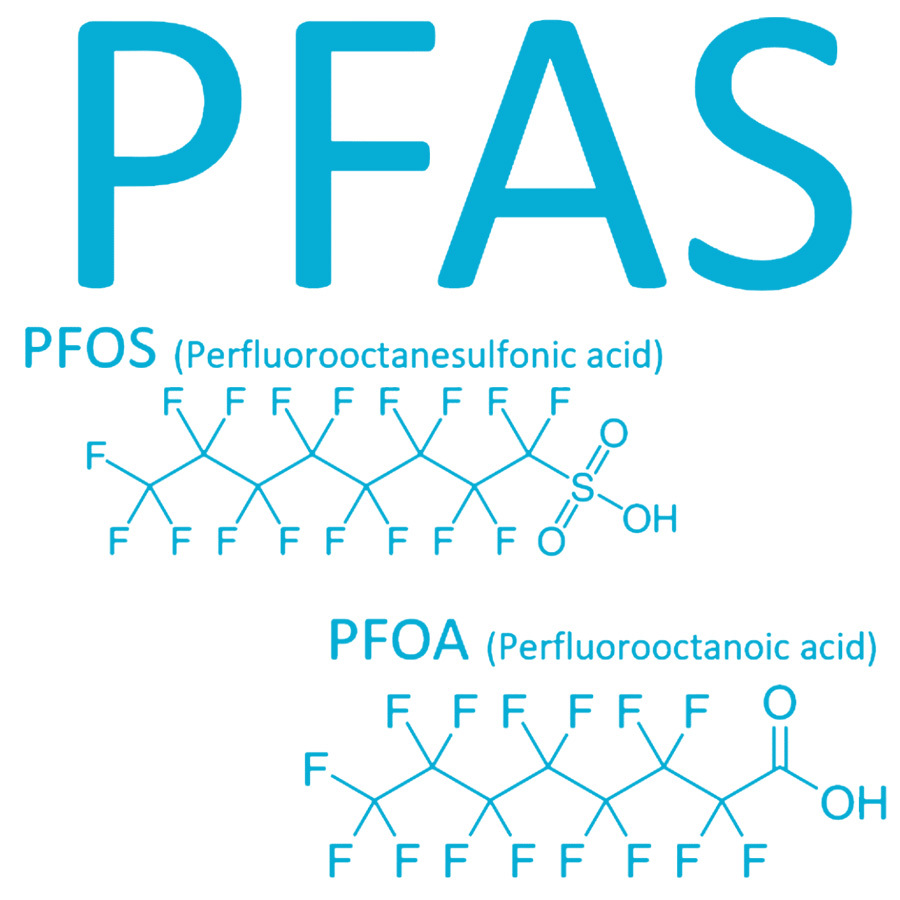

The principle of activated carbon in removing PFAS

Per- and polyfluoroalkyl substances (PFAS) are a class of artificially synthesized organic fluorochemicals in which all or part of the hydrogen atoms in carbon-hydrogen bonds have been replaced by fluorine atoms, with different functional groups attached at the ends. Depending on the type of functional group, they mainly include perfluoroalkyl carboxylic acids, perfluoroalkyl sulfonic acids, perfluoroalkyl phosphonic acids, perfluoropolyethers, fluoro-modulating polyols, and perfluorosulfonates, with the general structural formula CnF2n+1-R[3]. They possess characteristics such as hydrophobic and oleophobic properties, high temperature resistance, and the ability to reduce surface tension of water, and are widely used in the production fields of leather, textiles, paper, pesticides, fireproof materials, lubricants, coatings, personal care products, etc., earning them the nickname "permanent chemicals."

Research on the health and environmental impacts of PFAS began in the 1950s. It was not until the 21st century that the U.S. Environmental Protection Agency recognized their harm to health. On March 11, 2019, China's Ministry of Ecology and Environment and the State Administration for Market Regulation issued regulations prohibiting the production, circulation, use, and import and export of perfluorooctanesulfonic acid (PFOS) and its salts and perfluorooctanesulfonyl fluoride (PFOSF) except for acceptable uses. In June 2021, the United States proposed the "Prohibition of Perfluoroalkyl Substances in Cosmetics Act."

Starting from 2025, California and New York in the United States have already begun to ban the sale of clothing containing PFAS. An important reason for PFAS pollution is wastewater treatment and landfilling; they are highly stable, resistant to photolysis, hydrolysis, biodegradation, and metabolism by animals, posing a serious threat to the biological environment. Food, drinking water, indoor dust, and indoor and outdoor air are several main pathways for the general population to come into contact with PFAS. PFAS affect the health of organs such as the immune system, reproductive and developmental systems, liver, kidneys, pancreas, and are associated with cancer. Consumers find it difficult to determine the presence of fluorinated compounds in cosmetics based on their ingredients, so they should try to avoid using or limit the long-term use of makeup products that are too durable, waterproof, and difficult to remove.

Activated carbon (GAC/PAC) captures PFAS through physical adsorption and chemical interactions. The core mechanisms include:

1. Physical adsorption - Pore structure: The porous surface of activated carbon (micropores, mesopores) adsorbs PFAS molecules through van der Waals forces. Long-chain PFAS (such as PFOS, PFOA) are more easily adsorbed due to their stronger hydrophobicity.

2. Chemical interaction - Electrostatic interaction: PFAS carry a negative charge (such as sulfonic acid groups, carboxylic acid groups), and the surface charge of activated carbon can enhance adsorption through ion exchange or hydrogen bonding. Fluorine affinity: Some modified activated carbons (such as fluorinated ones) can selectively adsorb short-chain PFAS through fluorine-fluorine interactions.

Limitations of PFAS governance:

Activated carbon has a strong adsorption effect on long-chain PFAS (such as PFOS), but for short-chain PFAs (such as GenX), higher doses or modifications (such as loading metal oxides) are required. Natural organic matter (NOM) in water will compete with PFAS for the pores of activated carbon, reducing its efficiency.

The US EPA recommends the combined process of "activated carbon + reverse osmosis" (such as the Hoosick Falls project in New York State).

Regeneration issue: Waste activated carbon needs to be regenerated at high temperatures (>800℃), and PFAS may not be completely decomposed, posing a risk of secondary pollution.

|

Activated carbon in the field of treating and removing PFAS |

||||

|

Case Location |

Technical proposal |

Targeted pollutant |

Removal rate |

Key findings/challenges |

|

Zhejiang Fluorine Chemical Plant (China) |

Modified activated carbon (metal oxide loading) |

PFOS |

>90% |

Frequent regeneration is required and the cost is high |

|

Guangdong Electronic Industrial Park (China) |

GAC+(RO) |

PFOA |

>95% |

Efficient treatment of industrial wastewater |

|

Hong Kong Tseung Kwan O Waterworks (China) |

Activated carbon+(RO) |

Multiple PFAS |

>99% |

Treatment of by-products from seawater desalination |

|

Wilmington, North Carolina (USA) |

4-meter GAC filter bed + high-temperature regeneration |

GenX |

>95% |

The transportation cost is high and it relies on recycled kilns |

|

Blue Mountains Water Plant, Australia |

GAC+ion exchange resin |

PFSA mixture |

>90% |

Deal with the limits of the new regulations |

|

Municipal water supply in Kallinge, Sweden |

Large GAC adsorption tank |

Long-chain/short-chain PFAS |

>95% |

Continuous operation and low maintenance cost |

|

Rice University (USA) |

Flash Joule heating (GAC→ graphene) |

PFOA/PFOS |

>99.98% |

Zero net cost, resource utilization |

|

University of Queensland (Australia) |

PFPE-IEX+ (fluoropolymer adsorbent) |

short-chain PFSA |

>98% |

Renewable and recyclable |