Applications

Contact Us

Office Add:Room201,Unit2,Building7th,Huarunyuefu,No.27ChangxingSd, Wanbailin District,Taiyuan,Shanxi PR.China.

4.Solvent And Precious Metal Recovery

Activated carbon efficiently captures and recovers organic solvents through dual mechanisms of physical adsorption (van der Waals forces) and chemical adsorption (surface functional group effects), significantly reducing industrial costs and environmental pollution. Activated carbon efficiently enriches precious metals such as gold, silver and platinum through pore retention and surface reduction, solving the problems of resource scarcity and pollution.

|

The application of activated carbon in the field of recycling |

||||

|

The field of recycling |

Application scenarios |

Typical process |

Key indicators/cases |

|

|

Solvent recovery |

Industrial waste gas |

Printing/coating VOCs |

Fixed-bed adsorption + steam desorption |

The recovery rate of toluene is over 90% |

|

Purification of liquid medium |

Chemical fiber/pharmaceutical solvent |

Columnar carbon adsorption tower |

The recovery rate of carbon disulfide is 90% |

|

|

Fuel vapor |

Gas station/oil depot |

Low-pressure drop adsorption system |

Hydrocarbon residues are less than 0.1% |

|

|

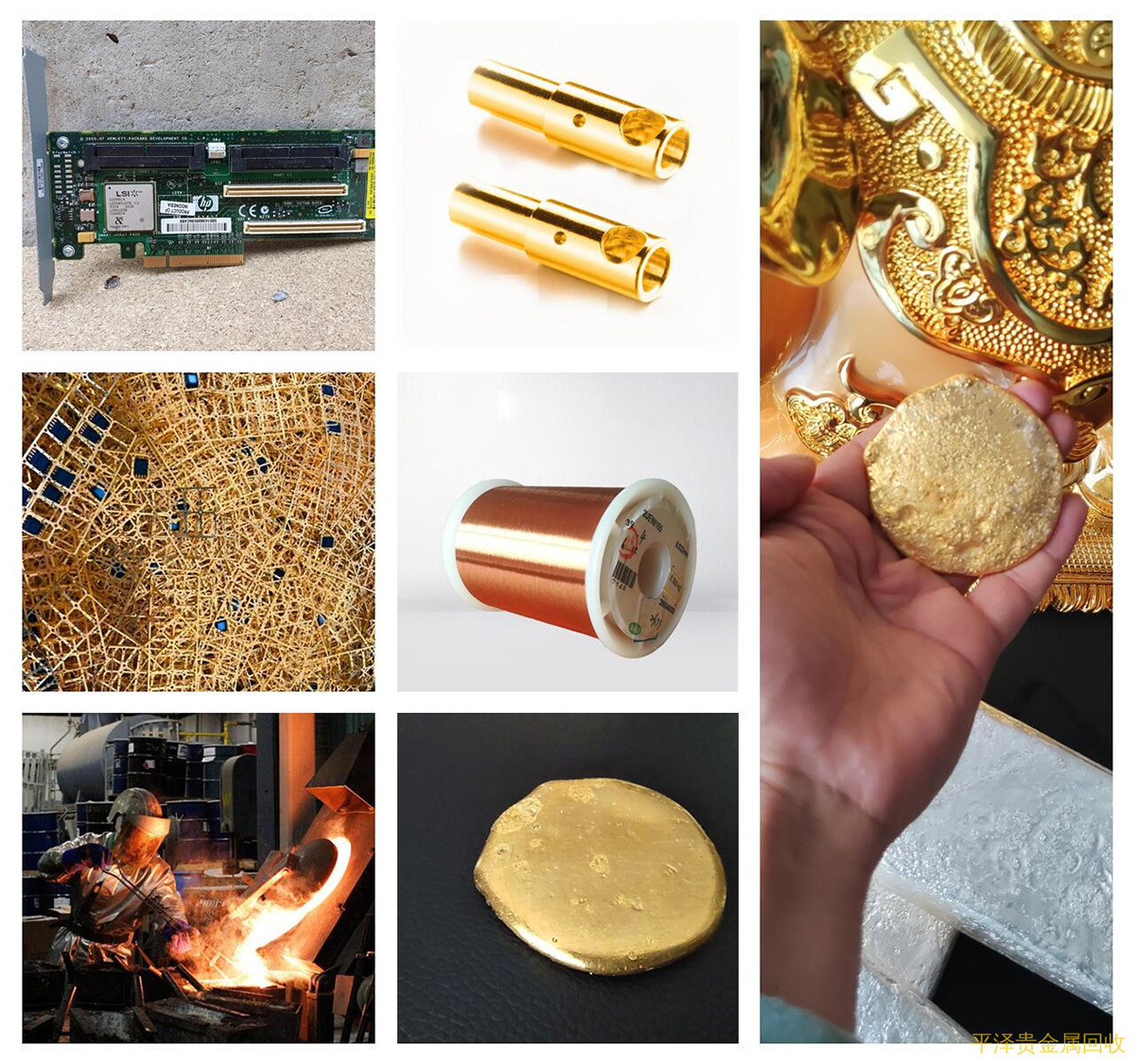

Precious metal recovery |

Electroplating effluent |

Gold-silver rhodium solution |

Electrolytic silver removal + activated carbon adsorption |

The purity of silver is 99.9% |

|

Industrial catalyst |

Platinum/palladium carrier |

Selective dissolution method |

Carrier α-Al₂O₃ reuse |

|

|

Electronic waste |

Waste batteries/circuit boards |

Acid leaching + activated carbon enrichment |

Silver recovery rate 98% |

|

|

Mine smelting |

Desorption of gold-loaded carbon |

Cyanide adsorption - high-temperature desorption |

The desorption rate of gold is over 95% |

|

|

Technical pattern |

Regeneration of activated carbon |

Pyrolysis of waste carbon |

High-temperature activation |

The iodine value has recovered to over 800 |

|

Green Island centralized processing |

Regional intensification of hazardous waste |

Shared facilities are uniformly recycled |

Enterprise costs have been reduced by 50% |

|